News

Silicone sealant, a polymer with adhesion, sealing, weather resistance and insulation, has multiple types. It's widely used in construction, photovoltaic, electronics, automotive, aerospace, medical and marine fields for bonding and sealing.

-

2911-2023

BIPV glass with printing technology

BIPV photovoltaic screen-printed glass is a special BIPV photovoltaic glass that uses screen printing technology to treat the glass surface to achieve photovoltaic power generation functions. Silk screen technology is a common glass process that forms a conductive film by printing conductive materials, such as silver paste or carbon nanotubes, on the surface of the glass. These conductive films can convert sunlight into electricity and output it to power the building's electrical system. BIPV photovoltaic screen printing glass has the following advantages:

-

1906-2023

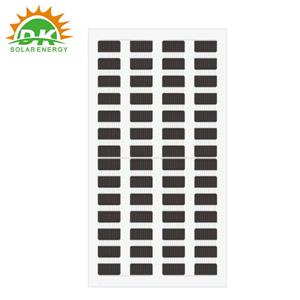

Xindongke energy rooftop solar panels for the Germany market.

Rooftop solar panels are photovoltaic (PV) panels that are installed on the roofs of residential, commercial, and industrial buildings to capture and convert sunlight into usable electricity. These panels consist of multiple solar cells made from semiconductor materials, typically silicon, which generate direct current (DC) electricity when exposed to sunlight.

-

2605-2023

We are at the SNEC 2023

On May 24, the 16th (2023) International Solar Photovoltaic and Smart Energy (Shanghai) Conference and Exhibition was officially opened to the audience. On the opening day of the exhibition, ready-made goods exploded in popularity. In addition to the photovoltaic industry leaders, Tongwei, Longji, Jinko, Trina ,solarspace and so on joined, attracting more domestic and foreign exhibitors to visit.

-

2804-2023

April 27, 2023 Hangzhou New Energy storage Conference

Recently, The new energy enterprises represented by Xindongke participated in the Haiju New Energy storage Conference in Hangzhou.

-

2703-2023

Various types of solar patterned glass

What is patterned glass? Patterned(textured) glass is also a kind of glass, and there are different called such as "Patterned glass", “Embossed glass “or "Rolled glass", which is belong a kind of flat glass, it is made of flat glass by calendaring molding. Meanwhile, It is with a transmittance in the optical characteristics of non-transparent and rich patterns. It has the characteristics of good decoration and is widely used in various places. A few of common patterned glass patterns include wood style, water pattern, long stripes, ice flower, snowflake, crabapple flower...all belong to patterned glass.

-

0401-2023

The market scale of monocrystalline silicon continues to expand, with photovoltaic as the main application field

The market scale of monocrystalline silicon continues to expand, with photovoltaic as the main application field. Monocrystalline silicon refers to the substance formed by silicon atoms in an arrangement, which is a relatively active non-metallic element crystal. Compared with polycrystalline silicon, monocrystalline silicon has the advantages of high photoelectric conversion efficiency, high mechanical strength, long service life, low fragmentation rate, and is widely used in photovoltaic power generation and semiconductor manufacturing.

-

1901-2026

What are the main application fields of silicone sealant?

Silicone sealant, a polymer with adhesion, sealing, weather resistance and insulation, has multiple types. It's widely used in construction, photovoltaic, electronics, automotive, aerospace, medical and marine fields for bonding and sealing.

-

3012-2025

Solar Drip Glue Panels: Technological Iteration Empowers Diverse Applications, Green Transformation Heralds a New Chapter of Growth

Solar drip glue panels have expanded applications from traditional outdoor lighting and small electronics to distributed PV, portable energy, BIPV, and special scenarios. The industry will advance toward high-performance materials, intelligent manufacturing, green products and diversified applications, with significant market growth potential. Customized demand is rising, and green environmental protection (e.g., bio-based resins, degradable encapsulation) will be the core direction, supported by policies. It will play a more important role in global energy transition.

-

1512-2025

Application of Two-Parts A B Silicone Adhesives in PV Modules (Including BIPV Modules)

The core application scenarios of two-component silicone adhesives are "structural bonding + long-term reliability requirements". They focus on core components of PV modules (such as frames and junction boxes) and connection parts between BIPV modules and building structures, making them particularly suitable for applications involving large-size modules, heavy loads, and extreme environments. Their selection must match module materials (glass, aluminum, backsheets), service environments (temperature, humidity, UV radiation), and mechanical requirements (bonding strength, displacement capacity). They are key materials ensuring the safe operation of PV modules and BIPV systems.

-

2811-2025

Perovskite Module Mass Production Efficiency Surpasses 22%

Perovskite PV modules have achieved a 22% mass production efficiency, on par with crystalline silicon modules. Single-junction and perovskite/crystalline silicon tandem technologies advance in parallel, with the latter’s R&D efficiency hitting 34.85%. China has built multiple GW/100MW-level production lines, with 50MW sales expected in 2025. Its low cost and flexibility suit BIPV, with 20GW global shipments projected by 2030.

-

0611-2025

Solar Energy Turns into a "Savings Pot" – The "Solar-Storage Duo" Makes 2025 Energy Life Amazing!

In 2025, the "solar-storage duo" of solar panels and batteries has gone mainstream, evolving from professional gear to daily energy stewards. Thin, flexible, and easy to install, they power homes (balconies as mini power stations), camping trips, remote areas, and even desert restoration. Boosted by perovskite and sodium-ion tech, they're smarter, more cost-effective, and eco-friendly, enabling energy independence and supporting global decarbonization.

-

1510-2025

High-efficiency transformation of PV Modules: Precise selection of solar ribbons becomes critical, full-spec supply drives performance release

In the critical period of PV modules transforming towards "higher efficiency, longer service life, and better scenario adaptation", the selection of solar ribbons has changed from "passive adaptation" to a core link of "active optimization". Enterprises with full-specification solar ribbon supply capabilities and customized services can help module enterprises establish a "battery technology - power target - application scenario" trinity selection system, fully unlock the performance potential of modules, and provide solid supply chain support for the goal of grid parity in the PV industry.