The performance comparison of EVA and POE for photovoltaic films

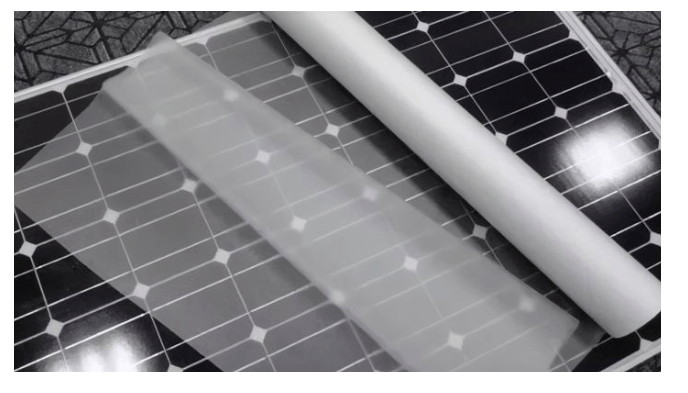

In the field of photovoltaics, EVA and POE has different own advantages and disadvantages. EVA is low in price, easy processing, storage resistance , fast in cross-linking, and has good bonding performance with solar glass & backsheets. The advantages of POE is in good material performance and anti-PID performance. Excellent PID resistance, high resistivity, high water vapor barrier rate, low temperature resistance and yellowing resistance.

Disadvantages of EVA mainly lie in that vinyl acetate is easy to hydrolyze under light, oxygen, and hot and humid environments, generating acetic acid, which corrodes the surface of the solar cell and the ribbon copper strip, and reacts with Na in the glass, generating a large number of free moving Na ions, causing power attenuation; At the same time, EVA is prone to yellowing under the photothermal environment, which affects the light transmittance and causes the overall power loss of the pv module.

The disadvantages of POE are that: the polarity of POE is low, and the polar auxiliary solvent precipitates to the membrane surface during the processing of the adhesive film, which makes the surface smooth and easy to shift; The processing is difficult, and the film lip is easy to hang; POE particles are more expensive than EVA. It is generally believed that in the next few years, the application proportion of POE particles in adhesive film particles will expand, mainly due to the following factors:

1. N-type battery: At present, the photoelectric conversion efficiency of P-type battery is close to the upper limit of 24.5%, while that of N-type battery is higher; The boron oxygen composite doped in silicon wafer of P-type battery will accelerate the potential attenuation, while the scale doped N-type battery has good anti attenuation performance. The PID effect of the N-type battery is more sensitive to the light receiving surface. The N-type module with large PID attenuation will also cause irreversible damage after the light recovers. At the same time, when the N-type battery is packaged with single glass, the water vapor barrier of the back plate is poor. Therefore, choosing POE adhesive film for packaging can reduce the overall water vapor transmission rate of the module and extend the service time of the module. Therefore, the promotion of the N-type battery can increase the amount of POE.

2. Large scale battery power: In recent years, the power of different types of battery modules has been significantly improved, the calorific value has increased, and the temperature will have a greater impact on the electrical properties of the battery, such as peak power and open circuit voltage. Therefore, the electrical performance requirements for packaging materials should be higher in recent years.

3. Thinning of cover plate glass and increase of double glass components: according to CPIA data, the current glass thickness mainly has three grades:<2.5mm, 2.8mm and 3.2mm; Among them, the market share of glass cover plate with thickness less than 2.5mm is 32%, which is expected to increase to about 50% by 2025. The thinner glass will require higher and higher performance of packaging materials, and POE has good mechanical strength and toughness.

EPE adhesive film has the advantages of both EVA and POE, and is an important development direction of adhesive film in the future. In addition, the excellent material properties of POE have huge application potential in automobile, wire and cable, machinery, shoe sole materials, hot melt adhesives and other fields. With the acceleration of localization process, POE will cultivate a larger market space.