development prospect of solar cell

The cell is generally divided into monocrystalline silicon, polycrystalline silicon, and amorphous silicon. Monocrystalline silicon solar cell is one of the fastest developed solar cells at present. Its structure and production process have been finalized, and the products have been widely used in space and ground. The solar cells are made of high purity monocrystalline silicon rods. In order to reduce the production cost, the solar cells used on the ground, such as single-crystal silicon rod solar energy, material performance indicators have been relaxed. Some can also use semiconductor device processing head and tail material and waste secondary monocrystalline silicon materials, after repulsing into solar cells dedicated monocrystalline silicon rod.

The polysilicon materials used in solar cells are mostly composed of a large number of single crystal particles, or are melted and cast with waste sub-monocrystalline silicon materials and metallurgical grade silicon materials. The process is to select the polycrystalline block material or monocrystalline silicon head and tail material with resistivity of 100~300 ohm · cm, after crushing, use 1:5 hydrofluoric acid and nitric acid mixture for appropriate corrosion, and then rinse with deionized water to be neutral, and dry. The polysilicon material was loaded with quartz crucible, and an appropriate amount of borosilicate was added to the casting furnace, which was heated and melted in a vacuum state. After melting, it should be kept warm for about 20 minutes, and then injected into the graphite mold. After slowly solidification and cooling, the polysilicon ingot is obtained. The silicon ingots can be cast into cubes so that they can be sliced and processed into square solar cells, improving the utilization of materials and facilitating assembly. The production process of polycrystalline silicon solar cells is similar to that of monocrystalline silicon solar cells. The photoelectric conversion efficiency of polycrystalline silicon solar cells is about 12%, which is slightly lower than that of monocrystalline silicon solar cells. However, the materials are simple to manufacture, power consumption is saved, and the total production cost is low.

Development of solar cells in China

China started the research of solar cells in 1958, the late 1980 s, China has successively introduced many solar cell production line, made the Chinese solar cell production capacity of 3 small plant of a few hundred kW suddenly raised to 4.5 MW, 4 factory this capacity until 2002, production is only about 2 MW. After 2002, the rapid enlargement of the European market, especially the German market, and the unexpected birth and extraordinary development of Wuxi Suntech Solar Power Co., LTD., have brought unprecedented development opportunities and demonstration effects to China's photovoltaic industry.

China has become the world's leading producer of solar cells. In 2006, the national production of solar cells was 438MW, and in 2007, the national production of solar cells was 1188MW. China has become the world's largest producer of solar cells, surpassing Europe and Japan. Production continued to increase in 2008, reaching 2 million kilowatts.

The annual growth rate of China's PV cell production is 1-3 times, and the proportion of PV cell production in the global output has also increased from 1.07% in 2002 to nearly 15% in 2008. The efficiency of commercial crystalline silicon solar cells has also increased from 13%-14% to 16%-17%. Overall, China's international market share and technological competitiveness of solar cells have increased significantly. In terms of industrial layout, China's solar cell industry has formed a certain agglomeration trend. In the Yangtze River Delta, Bohai Rim, Pearl River Delta and the central and western regions, solar industry clusters with their own characteristics have been formed.

Solar photovoltaic power generation will occupy an important seat in the world's energy consumption in the near future, not only to replace part of the conventional energy, but also will become the main body of the world's energy supply. It is expected that by 2030, renewable energy will account for more than 30% of the total energy mix, and solar photovoltaic power will account for more than 10% of the world's total electricity supply. By 2040, renewable energy will account for more than 50 percent of total energy consumption, and solar photovoltaic power will account for more than 20 percent of total electricity. By the end of the 21st century, renewable energy will account for more than 80 percent of the energy mix, and solar power will account for more than 60 percent. These figures are enough to show the development prospect of solar photovoltaic industry and its important strategic position in the energy sector. It can be seen that the solar cell market has a broad prospect.

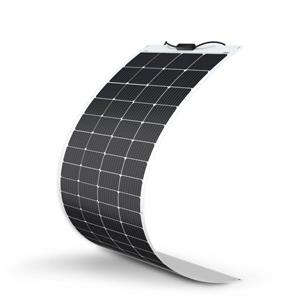

Solar cells mainly include crystalline silicon cells and thin film cells, their respective characteristics determine that they have an irreplaceable position in different applications. However, in the next 10 years, although the share of crystalline silicon solar cells will decline due to the development of thin film solar cells and other reasons, its dominant position will not fundamentally change; If thin film battery can solve the conversion efficiency is not high, the equipment used to prepare thin film battery is expensive and other problems, there will be a huge development space.