What is the difference between solar photovoltaic cells and solar photovoltaic modules?

Solar photovoltaic cells (PV cells for short) are used to convert the sun's light energy directly into electricity. The ground photovoltaic system largely uses silicon solar cells based on silicon, which can be divided into monocrystalline silicon, polysilicon and amorphous silicon solar cells.

The solar cell module is composed of high-efficiency crystalline silicon solar cells, ultra-white tempered glass, EVA film, transparent TPT backsheet and aluminum alloy frame. It has the characteristics of long service life, strong mechanical resistance to external force etc.

The structural forms of conventional components of solar cells are as follows, glass shell structure, bottom box component, flat panel component, and full glue sealing component without cover plate.

In short, solar photovoltaic cells are the core part of solar photovoltaic modules. Solar cells are mainly divided into crystalline silicon and amorphous silicon. The main raw material of crystalline silicon cells is silicon (commonly speaking, sand or sand grains are refined through a series of reactions) and then divided into monocrystalline silicon and polycrystalline silicon according to different casting processes.

Single-polycrystalline silicon wafers and polycrystalline silicon wafers undergo processes such as texturing→diffusion→etching→coating→sintering→testing to obtain solar cells that can generate electricity. Amorphous silicon is mainly an amorphous silicon thin-film solar cell made of amorphous silicon compounds as the substrate, and its market share is not large.

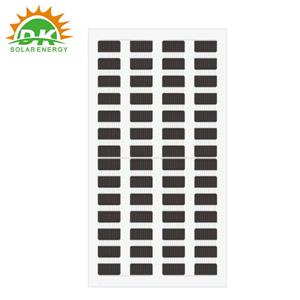

The core component of solar photovoltaic modules is cells. To put it simply, the manufacturing process of the module is the process of assembling the array of cells with encapsulation materials. The mainstream layout of battery sheets is 60 pieces and 72 pieces, which are arranged in series with ribbons to form a square array.

Solar photovoltaic module packaging materials mainly include backplane, EVA encapsulation film, transparent solar glass, aluminum frame and junction box, etc. The process mainly includes: material preparation→cell sorting→welding→stacking→EL test before lamination→lamination →EL test after lamination→framing→junction box installation→curing→cleaning→I-V test→packaging.

Xindongke supply all kinds of solar materials for solar pv modules, solar collector, solar energy/solar power system etc.

Welcome to visit us : www.dongkeenergy.com