ETFE film characteristics and applications

ETFE is a kind of fluorine-containing polymer thermoplastic material, the chemical name ethylene tetrafluoroethylene copolymer, in the 1970s, by the United States NASA and DuPont company jointly developed, and applied in the field of space.

Because ETFE has strong light transmission and heat insulation, it is soon widely used in various fields.

ETFE film has many properties that cannot be matched by other building materials:

(1) Resistance to temperature change, can be directly exposed to the temperature of -200℃ ~ +150℃;

(2) The transmittance of ETFE film can be up to 95%, does not block the transmission of ultraviolet light, transmission of natural light;

(3) Good thermal insulation performance, its K value can be up to 2.0W/m2·K. The energy dissipation index of a three-layer printing film for example can reach 0.77;

(4) Easy to clean, special anti-adhesion surface so that it has high pollution resistance, usually rain can remove the main dirt;

(5) light fire resistance, thickness is usually 0.05mm ~ 0.25mm, and the film quality is very light, only 0.15kg ~ 0.35kg per square meter. ETFE film reaches B1, DIN4102 fire grade standard, combustion will not drip;

(6) ETFE membrane is completely recyclable material, which can be reused to produce new membrane materials, or other ETFE products after separating impurities;

(7) Corrosion resistance can be combined with metal materials, strong adhesion characteristics of metal, close to the linear expansion coefficient of carbon steel, has excellent negative pressure resistance characteristics;

(8) Good weather resistance and long life, ETFE film service life is at least 25 ~ 35 years.

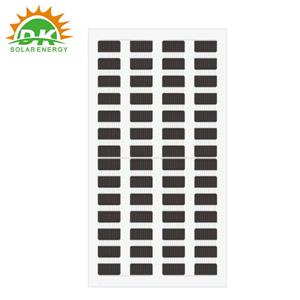

The common structures of ETFE membrane include monolayer membrane structure, cable membrane structure and inflatable membrane structure. Due to the initial surface curvature, the air pillow of the same size has a higher bearing capacity than the flat single ETFE film, so the double layer is the most common form of air pillow. ETFE membrane structure system requires steel structural members regardless of single layer or multilayer membrane.

ETFE film has high requirements on the steel structure. The steel structure connected with the film not only plays the role of structural force, but also plays the role of sealing the edge of the air pillow of the inflatable film. The production precision and installation process have high requirements. The outstanding characteristics of ETFE film, is the third largest membrane products after PVC, PTF membrane material, become the dazzling star of new building materials, especially suitable for greenhouse, exhibition, sports and other large space architecture.

ETFE film has excellent light transmission properties, especially suitable for the construction of artificial simulation of the natural environment of the building, such as greenhouse botanical garden. Green building, as an important part, should pay attention to sustainable development and create a better living environment for people.