Buy Supply Tabbing cell ribbon Wire For Solar Cell Company

- DONGKE

- HANGZHOU,CHINA

- 7-15DAYS

- 90T/Month

Technical Features of PV ribbon for solar cell product

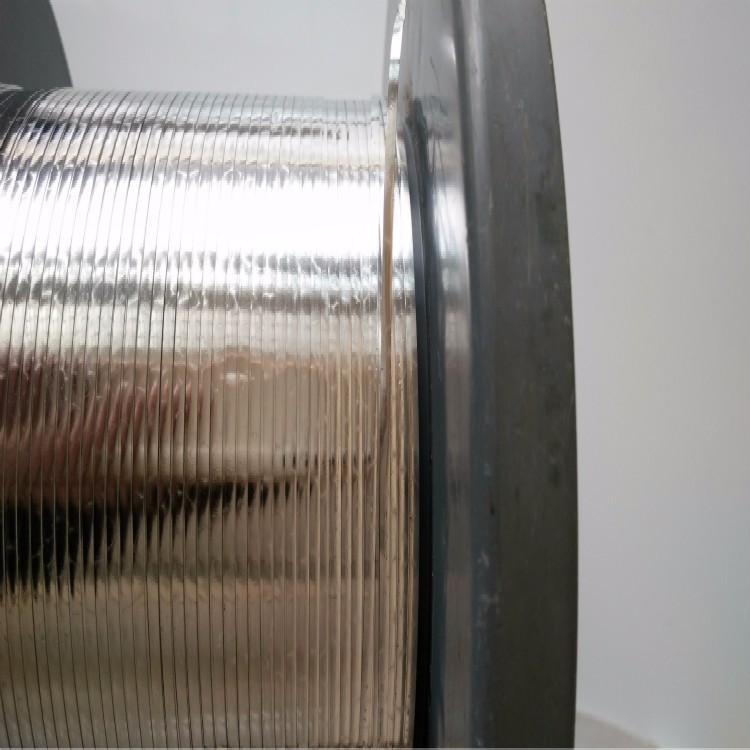

Electrolytic flat copper wire of high purity 99.95%, smooth, brilliant, cleaning. Out of scales and strokes, plated by dipping with tin and lead, or other lead-free chemicals compositions.

Buy Tabbing Wire For Solar Cell, Supply ribbon wire solar, cell ribbon solar wireCompany

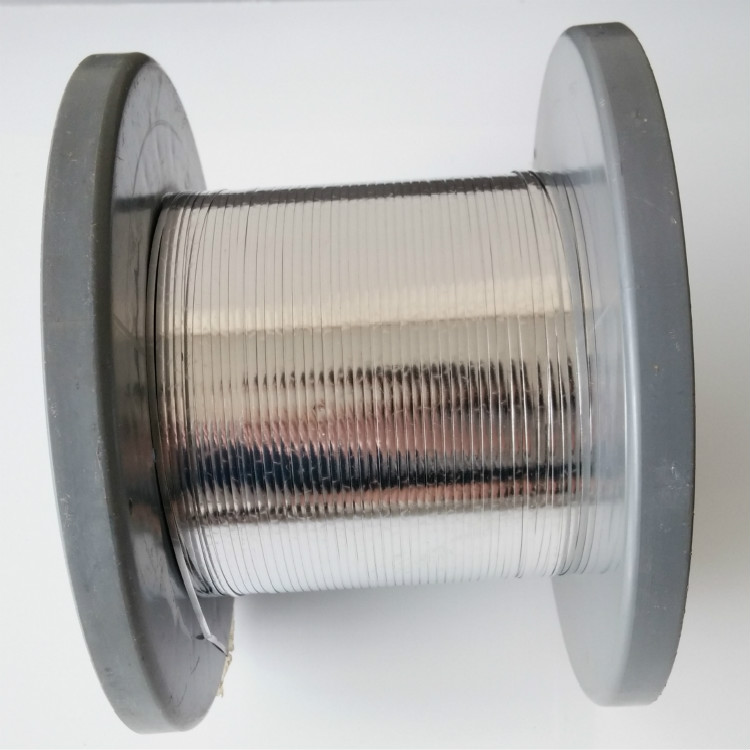

Tabbing Wire For Solar Cell

Solar Tabbing wire Mechanical Property:

1. Elongation: E-Soft>=20% U-Soft>=15%

2. Tensile strength:>=170MPa

3. Side camber: L<=7mm/1000mm

4. Soldering tin melting point: 180~230°C

Electric Resistivity of Copper:

TU1<=0.0618 Ω·mm2/m; T2<=0.01724 Ω·mm2/m

Core Copper of TU1 Off-Cu or ETP1:

1. Copper Purity >=99.97%, Oxygen<=10ppm

2. Resistivity: ρ20<=0.017241 Ω·mm2/m

Electric Resistivity of Ribbon:

(2.1~2.5)X10-2 Ω·mm2/m

The scope of Product specification:

1) Thickness Min: 0.04mm Max: 0.60mm

2) Width Min: 0.80mm Max: 20.00mm

Plated Thickness:

1) Hand-Soldering: 0.02-0.03mm per side

2) Machine-Soldering: 0.01-0.02mm per side

Composition of Plated Material:

1) Lead series products:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Lead-free series products:

A. Sn 96.5%, Ag 3.5%(Bi)

B. Sn 97%, Ag 3% and so on

About Tabbing Ribbon & Bus bar Ribbon

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

1. Tabbing Ribbon

Tabbing Ribbon commonly connects the positive and negative sides of the cells in series.

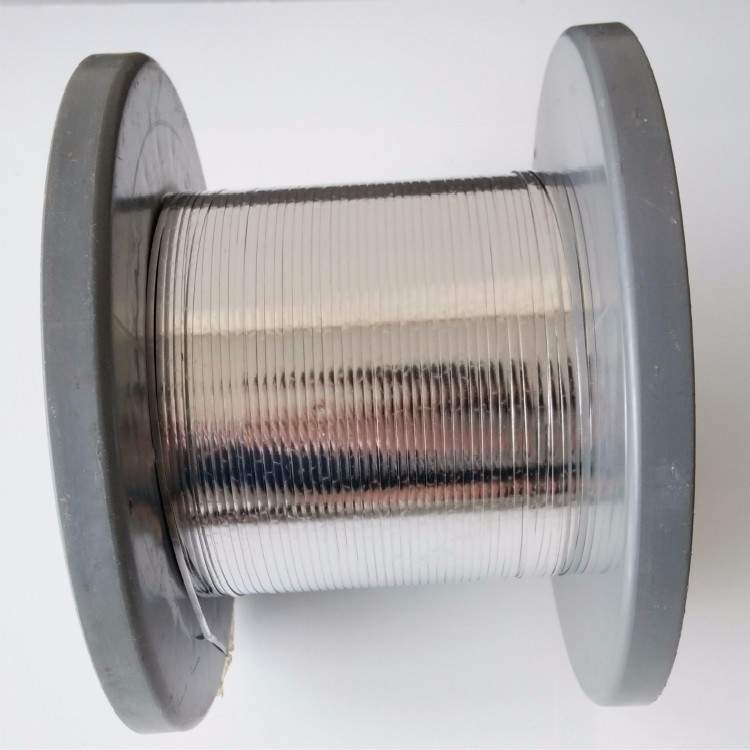

2. Bus bar Ribbon

Bus bar Ribbon concentrates the cell stringing into junction box and channels electrical current.

About Coating Alloy:

The coating type is determined by the customer’s design and demand. It is divided into leaded and dead-free coating. At moment the leaded coating type is widely used, but in the future it will be developed to lead-free coating type.

Main coating alloy types and melting temperatures as follows:

Specification of PV Ribbons/Tabbing Wire

| SIZE(mm) | THICKNESS(mm) | COPPER MATERIAL | TOLERANCE | ||

| W X T | Base Copper | Coat per side | Width | Thickness | |

| 0.6x0.12 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 0.8x0.08 | 0.0500 | 0.0150 | TU1 | ||

| 0.8x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.0x0.08 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 1.0x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.5x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.5x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.6x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.6x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.6x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.8x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.8x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 1.8x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.8x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 2.0x0.13 | 0.0800 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 2.0x0.15 | 0.1000 | 0.0250 | TU1 | ||

| 2.0x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 2.0x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 2.0x0.20 | 0.1500 | 0.0250 | TU1 | ||

Specification of Busbar Ribbon

| SIZE(mm) | THICKNESS(mm) | COPPER MATERIAL | TOLERANCE | ||

| W X T | Base Copper | Coat per side | Width | Thickness | |

| 2.3x0.13 | 0.1000 | 0.0150 | TU1, T2 | +/-0.05 | +/-0.015 |

| 2.3x0.15 | 0.1000 | 0.0250 | TU1, T2 | ||

| 2.5x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 2.5x0.18 | 0.1250 | 0.0275 | TU1, T2 | ||

| 2.5x2.0 | 0.1500 | 0.0250 | TU1, T2 | ||

| 3.0x0.10 | 0.0700 | 0.0150 | TU1, T2 | +/-0.05 | +/-0.015 |

| 3.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | ||

| 3.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

| 3.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

| 4.0x0.15 | 0.1500 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 4.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

| 5.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 5.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

| 5.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

| 5.0x0.35 | 0.3000 | 0.0250 | TU1, T2 | ||

| 6.0x0.15 | 0.1000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 6.0x0.18 | 0.1500 | 0.0150 | TU1, T2 | ||

| 6.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | ||

| 6.0x0.23 | 0.1800 | 0.0250 | TU1, T2 | ||

| 6.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

| 6.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

| 6.0x0.35 | 0.3000 | 0.0250 | TU1, T2 | ||

| 7.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 7.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

| 8.0x0.20 | 0.1500 | 0.0250 | TU1, T2 | +/-0.05 | +/-0.015 |

| 8.0x0.25 | 0.2000 | 0.0250 | TU1, T2 | ||

| 8.0x0.30 | 0.2500 | 0.0250 | TU1, T2 | ||

| 8.0x0.40 | 0.3500 | 0.0250 | TU1, T2 | ||

Technology Process

1,Forming of round wires to flat wires through drawing and rolling

2,Heat tretment

3,Hot-dip tinning

4,Precise spooling

Copper base is the oxygen free copper strips perssed by ultra-precision rolling equipments imported from germany

It is sleek and no bur edge, the soft hardness can be adjusted by customer requirement.

With the particular formula technology, the tin alloy coat is produced by professional hot-dipping tinning equipments imported from Japan. Coat suface is bright and even, it has atable performance and strong antioxidant which helps to imporve the welding yield. Its thickness can be adjusted by customer requirement.

The ribbon can be made to order according to solar module and it's dimension